PRODUCT

CONTACT US

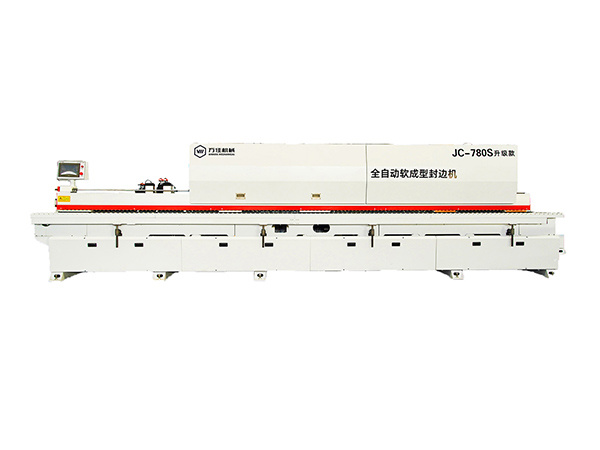

780S semi-pass handle-free edge banding machine

Category:

Product Detail

JC-780S is a fully automatic soft forming edge banding machine.

It mainly produces J-type all-pass, C-type all-pass, left half-pass, right half-pass, and middle handle. One machine can make 5 styles.

Heavy-duty pressure beam transmission ensures a smoother processing process; touch-screen intelligent control requires only one button to switch between functions; the conveying motor adopts a 4-kilowatt edge-banding machine dedicated reduction motor, a heavy-duty edge-banding machine bottom beam, and a Haisen chain block. Special chain. The board feeding is more stable, and the processing speed can reach 8m/min. The whole machine is equipped with 4 milling motors and two sets of 2.2kw pre-milling motors, which are used for pre-milling of plates to remove burrs. Two sets of 6.0kw high-power milling motors are interlaced with each other and equipped with two sets of servo control motors to make the milling more perfect and ensure that the profile is smooth and free of concavities and convexities. And the chamfering function is added, which can effectively remove the edges and corners of the board, making the edge sealing more perfect. The upper glue pot design and the selected mesh-type glue shaft make the glue coating more uniform. The original soft molding technology is equipped with a regional constant temperature system, industrial-grade hot air cannon and infrared baking lamp to ensure that each module is processed smoothly and can adapt to any environment without being affected by temperature. For rough trimming, fine trimming, and profiling polishing, we all use branded equipment. Only with this complete machine configuration can the soft forming edge banding machine be more stable, efficient, precise in processing, and easy to control.

Process flow: Pre-milling 1 → Pre-milling 2 → Milling 1 → Milling 2 → Chamfering → Gluing → Heating system → Soft forming and pressing → Edge strip cutting → All in one step → Rough repair → Fine repair → Profile polishing

Product Detail

JC-780S is a fully automatic soft forming edge banding machine.

It mainly produces J-type all-pass, C-type all-pass, left half-pass, right half-pass, and middle handle. One machine can make 5 styles.

Heavy-duty pressure beam transmission ensures a smoother processing process; touch-screen intelligent control requires only one button to switch between functions; the conveying motor adopts a 4-kilowatt edge-banding machine dedicated reduction motor, a heavy-duty edge-banding machine bottom beam, and a Haisen chain block. Special chain. The board feeding is more stable, and the processing speed can reach 8m/min. The whole machine is equipped with 4 milling motors and two sets of 2.2kw pre-milling motors, which are used for pre-milling of plates to remove burrs. Two sets of 6.0kw high-power milling motors are interlaced with each other and equipped with two sets of servo control motors to make the milling more perfect and ensure that the profile is smooth and free of concavities and convexities. And the chamfering function is added, which can effectively remove the edges and corners of the board, making the edge sealing more perfect. The upper glue pot design and the selected mesh-type glue shaft make the glue coating more uniform. The original soft molding technology is equipped with a regional constant temperature system, industrial-grade hot air cannon and infrared baking lamp to ensure that each module is processed smoothly and can adapt to any environment without being affected by temperature. For rough trimming, fine trimming, and profiling polishing, we all use branded equipment. Only with this complete machine configuration can the soft forming edge banding machine be more stable, efficient, precise in processing, and easy to control.

Process flow: Pre-milling 1 → Pre-milling 2 → Milling 1 → Milling 2 → Chamfering → Gluing → Heating system → Soft forming and pressing → Edge strip cutting → All in one step → Rough repair → Fine repair → Profile polishing

Related Videos

Related Products

Product Consultation