PRODUCT

CONTACT US

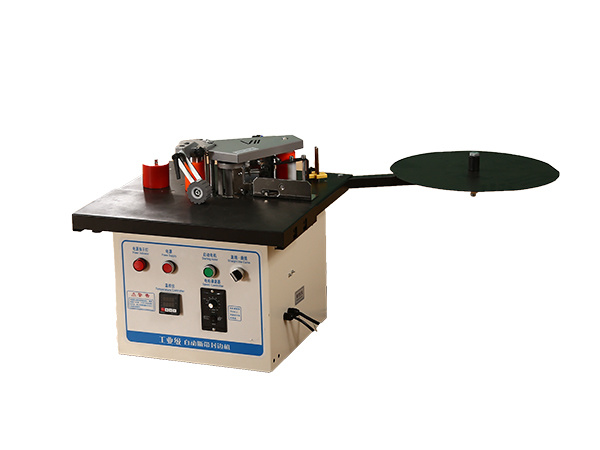

Portable edge banding machine

The edge banding machine automatically breaks the tape and is glued on both sides, making it lightweight and easy to carry.

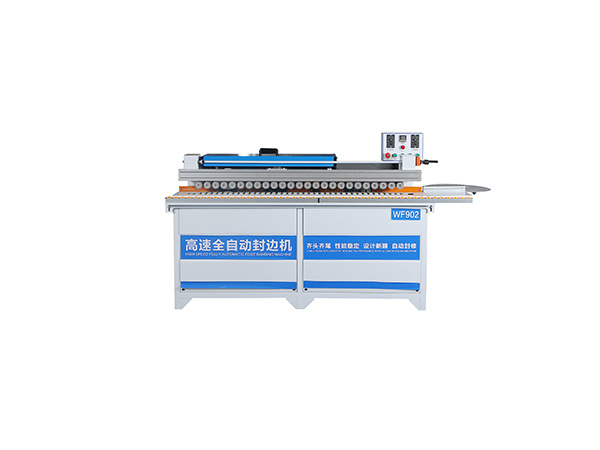

WF902 high-speed fully automatic edge banding machine. The machine adopts an integrated aluminum alloy thickened pressure beam, double-row press wheel track automatic plate movement, 4000ML large-capacity glue pot design, large-diameter vacuum cleaner, secondary scraping and finishing, large Powerful upper and lower polishing, starting from the plate, it goes through pasting, trimming, head to tail, and finishing and polishing in one piece.

802 edge banding machine is a high-speed, fully-automatic edge banding machine with a large glue pot capacity that can be used for edge banding, profiling trimming, and cross polishing to shape the board in one go.

The appearance of the F-200 full-line high-speed fully-automatic edge banding machine is almost the same as that of the Jidong large-scale automatic edge banding machine. The structure is similar, with a main frame body and a modular structure. Compared with traditional small edge banding machines, the integrated structure of the table is more stable, easier to maintain, and the double guide rails can apply glue smoothly. No leakage. Keep gluing. Trimming head-on structure module, high-speed brushless spindle motor, dual-cylinder follow-up copying. Scrape the edge up and down to remove excess residual edges. The glue line will not be obvious and the edge sealing will be more beautiful. Polish the top and bottom to make the edge strip round and not cut your hands. Double guide rail chain blocks, reinforced 100*50 widened beams to ensure the parallelism of plate transmission, and double rows of inclined rollers to prevent deviation in transmission.

The edge banding machine has a pure aluminum integrated pressure beam and is fed by crawler tracks throughout the entire process. Edge sealing, edge trimming, high-power polishing, edge scraping, and glue removal are all done in one go. It imitates a large-scale fully automatic internal structure, and edge trimming is more stable. The machine itself has a built-in dust collection function, which is suitable for small furniture factories. use.

The edge banding machine has a full linear pressure beam, automatic feeding, edge banding, edge trimming, glue line cleaning, cross polishing, and large-diameter vacuuming, with a close-fitting vacuuming effect of 99%.

WJS190 uses a square rail slide to achieve profiling trimming. It uses a Sichuan 4-edged alloy round knife to trim the board into a round shape. It automatically aligns the edges. It uses a large-diameter vacuum to achieve a close-fitting vacuuming effect of 99%. For crawler transmission, we use steel rod slide rails, which makes the conveying more stable and the real materials can be seen!

The WFS-210 edge banding machine is fully automatic and operates more smoothly. It has steel plate guide rails and front and rear profiling glue pots. It can easily and evenly apply glue to the board, making the edge banding tighter. The elastic device presses twice and the frame motor base makes board sealing more convenient and hassle-free. Shaking, trimming motor up and down, left and right profiling trimming, precision slide, adhesion and vacuuming, glue line cleaning, flexible edge scraping function, cross polishing, one-time molding.

WFS-910H full linear edge banding machine, edge banding, edge trimming, glue line cleaning, polishing and molding in one go. It can seal large boards of 1.22*2.44m or narrow boards of 2.5cm. It has double-row press wheels, full tape feeding, and high box design.