PRODUCT

CONTACT US

Product

The WFS-210 edge banding machine is fully automatic and operates more smoothly. It has steel plate guide rails and front and rear profiling glue pots. It can easily and evenly apply glue to the board, making the edge banding tighter. The elastic device presses twice and the frame motor base makes board sealing more convenient and hassle-free. Shaking, trimming motor up and down, left and right profiling trimming, precision slide, adhesion and vacuuming, glue line cleaning, flexible edge scraping function, cross polishing, one-time molding.

WFS-910H full linear edge banding machine, edge banding, edge trimming, glue line cleaning, polishing and molding in one go. It can seal large boards of 1.22*2.44m or narrow boards of 2.5cm. It has double-row press wheels, full tape feeding, and high box design.

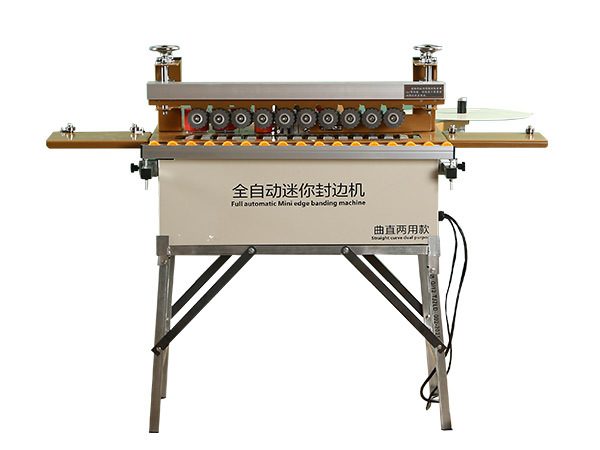

Slide table mini edge banding machine

The edge banding machine table is equipped with power-assisted rollers, the push plate is smoother, the belt is automatically broken, and it is light and easy to carry.

Mini automatic feeding edge banding machine

The edge banding machine automatically breaks the belt, integrates the pressure beam, and provides full track feeding, which makes edge banding more convenient. Two sets of elastic devices make the edge banding strip more firmly pressed.

Polishing, sealing and repairing all-in-one machine

The edge banding machine automatically breaks the tape and can seal, trim and polish the edges. The machine itself has widened fluent strips, which can assist in sealing large boards.

Head to tail edge banding machine

The edge banding machine can be used for both straight and curved purposes. It has automatic belt feeding for straight edge sealing, an integrated pressure beam, and full crawler feeding, edge banding, edge trimming, and polishing. It can be vacuumed and the board can be formed in one go. Double-sided glue coating for special-shaped sealing, one machine for multiple uses.

A high-power double saw core is equipped with three motors, a small motor for marking, and a large saw for cutting boards. It is also equipped with a vacuum fan and an external switch design. When replacing the saw blade, you can control the lifting and lowering of the large motor with a button. The machine is compact. Easy to transport.

Integrated brushless manual saw head

The brushless and dust-free saw has low noise and does not disturb people. It uses a high-power servo motor to cut panels more smoothly. External switch design makes it more convenient to switch the motor on and off.

WT10 dust-free double saw adopts precision slider design, optical axis lifting structure, easier motor adjustment and higher precision.